Foundation & Wall Repair

Are your walls cracked and bowing? If the answer is yes, you need to take action immediately to protect your investment from future expensive repair. In most cases if you identify and repair issues with your foundation walls early in its movement, you can save thousands. Early detection and prevention will save you money and protect your investment for years to come.

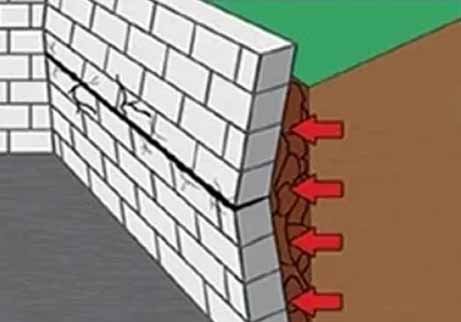

Bowed Walls

Settlement in Foundation Footers

There are many reasons why foundation footers can settle. Evidence that your footers have settled will generally be shown by a stair stepping crack in your foundation wall that has separated. This can be repaired using many different methods. Once Chad has inspected your property, he will discuss cost-effective methods to resolve this issue. In most cases, the footer needs to be stabilized using Helical Piers. Click here to learn more about Helical Piers.

Structural Cracks in Poured Walls

There are few things in life that can be certain, but one of them is that concrete will get hard and concrete will crack! Generally in horizontal concrete like your basement floor or concrete driveway, the installers will put saw cuts or tooling marks to help control where and how the concrete will crack. This is simply not possible in vertical concrete like your foundation walls. Although horizontal cracks are rare in foundation walls, you will have vertical cracks. Vertical cracks will generally occur in areas such as beam pockets, midpoint of long walls (20 feet or more) and windows. When concrete cures, it shrinks and causes cracks. Most general shrinkage cracks are fine, as long as they are not leaking water or showing displacement. Displacement is when the lateral forces on the wall have pushed the wall inward. The best way to tell the difference between a shrinkage crack and displacement is to run your finger across the crack. If your finger catches on the crack, there is displacement and it needs to be repaired immediately.

The most effective way to repair a structural crack in a poured wall is using a process called epoxy injection. This is a simple and non-intrusive process that takes between 90-120 minutes. We will place injection ports along the crack from bottom to top. Then we add a surface paste over the crack to hold in the material during the injection process. Once the paste has hardened, we start at the bottom port and push a two-part epoxy material into the crack until it comes out of the port above it. We cap off the bottom port to hold the material in and continue the process on the remaining ports above until the crack is filled.

Once the crack is filled, the epoxy bonds to the concrete and hardens. The epoxy will harden approximately 3-4 times the strength of the original concrete around it. This will keep the crack from moving any further, thus stabilizing the wall.